9 Warehouse Problems and Solutions

To outsiders, warehousing often looks straightforward — just store products on racks until they’re needed, but industry insiders can only wish that it was that simple! Managing inventory has always been challenging, and trends in logistics management continue to make it harder every day.

Here’s a look at nine of the top warehouse problems and solutions to those problems that might help ease the load:

1. Inaccurate Inventory

Incomplete or inaccurate records often reveal themselves when a warehouse worker attempts to retrieve product from an expected location and it is not there or then they are directed to store product into a location that’s already full. Time and effort are wasted making physical checks and trying to correct error, often leading to delayed shipments and mis-picks.

Many of these issues are a result of less-than-optimal, burdensome manual processes that result in producing inaccurate data in the system. One solution is the incorporation of warehouse execution system (WES) applications and other systems that help to automate data-recording activities.

2. Redundant Activities

The existence of unnecessary, excessive handling of product plagues many warehouses, with cases or pallets being moved through several intermediate locations. Often, though, redundant activities can be less obvious. Duplication of information and duplicate data entry are examples of major timewasters.

What to do about it? Ask the team for ideas and, for a different perspective, consult with specialists in warehouse technology. A new layout might help, or maybe it’s time for investment in a modern WES.

3. Suboptimal Picking

If picking isn’t done efficiently, obviously time and money are wasted. Yet what does “efficient” look like? Ideally, picking minimizes time and movement, with the goal of maximizing units picked per hour. Warehouse automation can help with this by implementing automated retrieval and picking solution.

Not taking full advantage of data reading and entry technologies can also lead to suboptimal picking. Mistakes are made, potentially creating double handling and inventory issues.

The solutions are to standardize processes, including pick routes, and invest in appropriate automation for data handling/inventory management.

4. Poor Layout/Space Utilization

Achieving good space utilization has taken on new urgency with the rise of e-commerce. In fulfillment centers, there’s more movement and picking, increasing the cost of poor layout. Also, warehouse locations close to population centers often occupy more expensive land, which drives up costs.

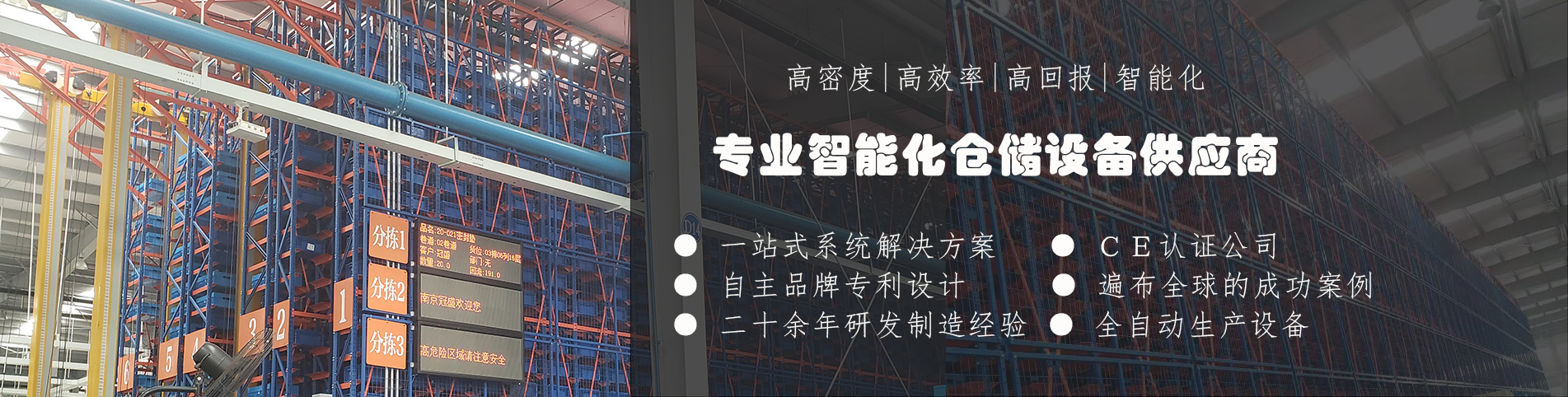

Using a WES data to identify the most frequently picked items and then, rearranging storage locations to minimize distance traveled for picking these. Additionally, explore what new racking and storage technology could do to positively effect utilization. For example, a high-density automated storage and retrieval system (AS/RS) could significantly increase space utilization.

5. Product Diversification

Aligned with the growth of fulfillment centers, warehouses are holding a wider variety of items than ever before. While WES capacity isn’t usually one of the top warehouse problems, the increase in picking work most definitely is. As with space utilization, the answer lies in using WES to determine optimal storage algorithms to increase picking efficiency. Also, look at ways of reducing the physical work involved in fulfilling these picking tasks. It’s possible that an AS/RS system is the ideal answer.

6. Seasonal Demands

How do you allocate space as workload varies seasonally? Configuring the warehouse for peak demand means potentially leaving areas underutilized the rest of the year.

Warehouse automation products offer solutions. Pallet flow systems, new racking, and more capable lift and boom trucks can also boost units per hour handled, as can a complete AS/RS. Increasing capacity this way provides “headroom” for the busy periods without saddling the operation with poor space utilization the rest of the year.

7. High Labor Costs

Managers at distribution and fulfillment centers are under increasing pressure to reduce costs while improving service levels.

Picking is still, for now, a highly manual task, although solutions continue to emerge. Consider how technology can increase pick rates and how pallet flow systems and AS/RS technology should be part of the solution.

8. Avoiding Product Damage

There are myriad of reasons that product can be damaged in a warehouse. Sometimes this is found during picking.

Modern racking and pallet flow systems can move product more carefully than older technology. Cases are decelerated and zero pressure systems maintain a minimum separation to prevent damages. AS/RS is, once again, another solution.

9. Handling Returned Items

File this under “poor layout” if you want, but it’s a problem big enough to warrant a separate heading. As e-commerce has grown, so too have return volumes. A common problem with an informal or haphazardly planned system incurs double handling. What’s more, poor record keeping results in workers spending time resolving queries.

As a potential solution, start by understanding the product flow and documenting the activities being conducted in the warehouse. From there, move into standardization and assess how technology could help. Automation providers experienced in assessing warehouse problems and providing efficient solutions may have ideas you haven’t considered.

Industry-Appropriate Solutions

Specialists at a company like Westfalia Technologies realize that there’s no one-size-fits-all answer to every warehouse problem. Our professionals take the time to understand the issues and challenges faced by each customer in all the industries that we serve. As the facts are gathered will they begin the process of developing the appropriate solutions, whatever form they may take — AS/RS, WES, or conveyor and pallet flow systems.

86-25-5279 6106

86-25-5279 6106

Contact

Contact

Download

Download